First printing project after a while

With most of the software and firmware ready, I was up to do some printing. I recalled the hardship of leveling my bed, and thought that a good staring point would be nobs to adjust the heated bed level.

I am using M3 bolts. Following Wikipedia, I figured out the step of standard screw, which is 0.35mm for every revolution. By making a 7-teeth rosette, with every "leaf" turn, I would change the bed's height by 0.05mm. Sounds awesome, lets design. You can get the CAD from my public Onshape project here.

The slicer: time for Ultimaker

During my stay in Germany I had the pleasure of meeting people who were also hooked on 3d printing. I recalled Johannes speaking highly about Ultimakers software as a "printing command center". At that time (like 7 years ago) Ultimaker was actually supporting RepRaps and print-over-USB. Sadly for me - not anymore. Greater reliability of SD card control or wireless control with remote hubs, Ultimaker removed the option to control the printer over the cable. Still, one could add a custom printer that was controlled by Repetier firmware! I decided to relieve Ultimaker from the control duty, relying on good old Pronterface, and use Ultimaker as plater and slicer.

In the beginning I was a bit overwhelmed with the amount of options available. Things have definitely moved on. Yet the overall setup was rather self-explanatory and easy to understand. I definitely appreciated the tooltips over every setting.

With slicing done and g-code loaded up to Pronterface, it was time to print!

The prints

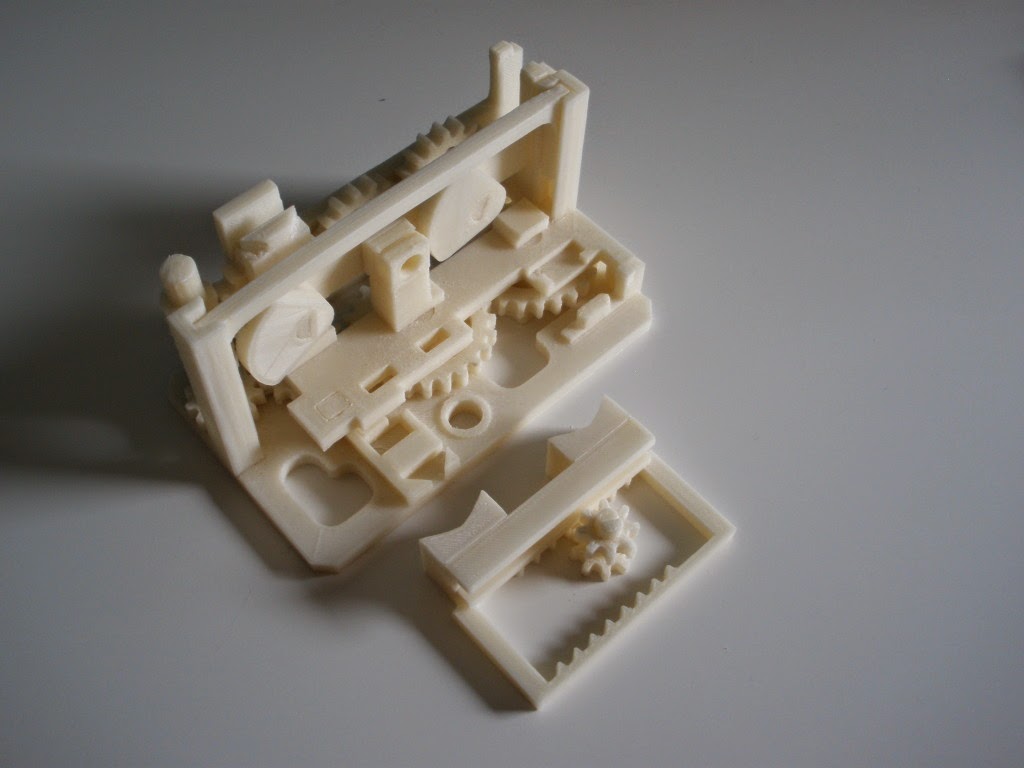

The first prints were quite challenging due to reasons not clear to me at that time. Although the first layer seemed to nicely fill and the following layers appearing, something was off.

The image is a small compilation of the attempts made. There were problems with delamination, constant nozzle blockages, driving bolt "eating" filament and clogging teeth... Interestingly enough supposed that I "survived" the first solid layers, paused the printer to clear the hobbed bolt, then for the infill layers things would go rather smoothly. Only after getting to top full layers, the issues would appear again, often making the printer not extrude for the final layer (or two). Fortunately, since these were work-parts I did not care if the layer was missing or if parts ended up a bit skewed. After an evening or two of attempts, I was holding a set of 4 bed adjusters. I mounted them on the printer and have been using them with great success since then! Bed leveling was never easier!

Oh and yes, I am aware that these could/should be mounted on the bottom, not to interfere with the extruder. I am actually planning to re-mount them, but for now they are OK and it is easier for me to manipulate them that way. Also the Y-axis movement prevents me from using last 2cm of the bed, and the glass bed clippers (in the background) also remove extra 1cm from each side. I might work on this at some time but for now I do not need the whole bed anyway.

In the next post I will show the X- and Y- belt tensioning elements plus I will reveal what was wrong with the extrusion settings.