Ladies and Gentlemen,

It is my honor to present the crown

achievement of Pawel’s 3d printing craftsmanship so far! The

Walking Beam project! Brace yourselves- a long post is coming!

It would be good at the beginning to

explain what is a walking beam and how did I get the idea to make

one? I am working in sales of steel industry at the moment. We are

dealing with lifting of steel coils that weight tens of tons. A coil

can be sometimes 2 meters in diameter and weight for example 35 t. In

order to speed up feeding of processing lines, the coils are put on

“saddles” and then transported by special cars or by walking

beams. A picture tells a thousand words, so here is a scheme of

walking beam in action.

The coil rests on a saddle (1). The

beam is lifted with the coil resting on it (2). Then it moves to next

position and is lowered (3). The coil now rests on next saddle and

the beam moves back to the starting position (4). It is easy to

imagine that the beam can be longer than 3 saddles, and that it can

transport more coils at the same time- smart and very effective.

I decided to make a model of such a

machine that would transport wine corks.

The big industrial walking beams are

driven by powerful hydraulic cylinders. My goal was to make

everything mechanic (gears). I also wanted to have only one “power

source”- a single rotating handle that would go in one direction

and allow for all the cycle to take place. Furthermore it would be

fun to rotate the handle several times before the cycle was done.

The target were 3 handle rotations to lift/lower the beam and 5

rotations to move it left/right.

The question was: how do we make the

machine first to lift the beam (keeping it still in horizontal

direction), then move it only left, then down and then right? I

needed two systems: lifting and transverse. Each needed to have its

“action phase” (move or lift) and a “pause phase” (when the

second system would be working). They should also be able to

automatically switch between each other. And of course all had to be

driven by one handle going rotating in one direction :)

First let’s talk about the lifting

system. The heart of the mechanism I used looks the following:

I divided 360 deg into 3/16, 5/16,

3/16 and 5/16, that is 67.5 deg, 112.5 deg , 67.5 deg and 112.5 deg

(three rotations for lifting and five for transverse, remember?). The

5/16’s are parts of two circles representing “pauses”. Their

radius difference is equal to desired lifting distance. The 3/16’s

are the lifter’s “action phases”. The beam is resting on the

top of the lifter, which is rotating with constant speed. The

animation below demonstrates how it works.

Now it is time for transverse

movement. How to make it go left, pause, then right and pause when

the drive is rotating in the same way? At first I thought about some

particular half-gears with reducers and different number of

intermediate gears. This seemed a bit complicated though- it will do

nicely as another project. For my walking beam I used a simpler

solution. I fixed the transverse drive gear (TDG) in

one spot and made it rotate with constant speed in one direction.

Then a frame was put “around it” with teeth on the top and

bottom. Depending on whether the TDG is touching top or bottom teeth,

the frame would move left or right. The lifting system was used to

change which teeth are touched. I got the “action phase”,

“pause”, “action” and “pause”. In addition, to prevent

unwanted movement, final teeth in the frame were removed. The

schematic animation below shows the idea in action:

This system has one big flaw- it can

only transport the corks in one direction. At the same time it is

simpler to implement and more robust to inaccurate synchronization.

Having the idea fixed I started

designing the machine. I calculated gear reductions, movement

distances, general overlay- well, some theoretical stuff. Then it was

FreeCAD time. Finally I had an excuse to learn a bit Python. It was

not very tempting to make every gear or spiral “by hand”, and

having a nice procedure that could do it for me made my life much

easier. Especially that there were lots of different gears to be

done.

I was advised by the organ between

my ears to first allocate the moving elements in space and then think

how to make the supports and frames. The machine was supposed to be

compact and should allow for easy dismounting and access to the

parts. And of course each element was to be designed in a way that

would allow printing it. It took quite a few evenings, few weekends

and finally I got the design ready:

Doesn't it look awesome already?

One could ask: “why didn't you

start printing when you had some parts of the design ready”? Well I

did. At least few gears that I knew that were in their “final”

form were printed during FreeCAD period. The rest was being modified

a lot on the way. Fixing any shape by printing it puts a big

constraint on other part’s shape. Being perfectly honest- I made

one or two design mistakes on the way but in the end the errors were

insignificant. I was able to repair them with few moves of a file

and a tiny bit of glue.

In general all the parts were

printed in their desired final shape and required only surface

cleaning from the printing residual trash. Most important elements’

surfaces were additionally treated with acetone to get a nice smooth

finish. Also due to 3d printing limits five parts were intended to be

made of several elements glued together.

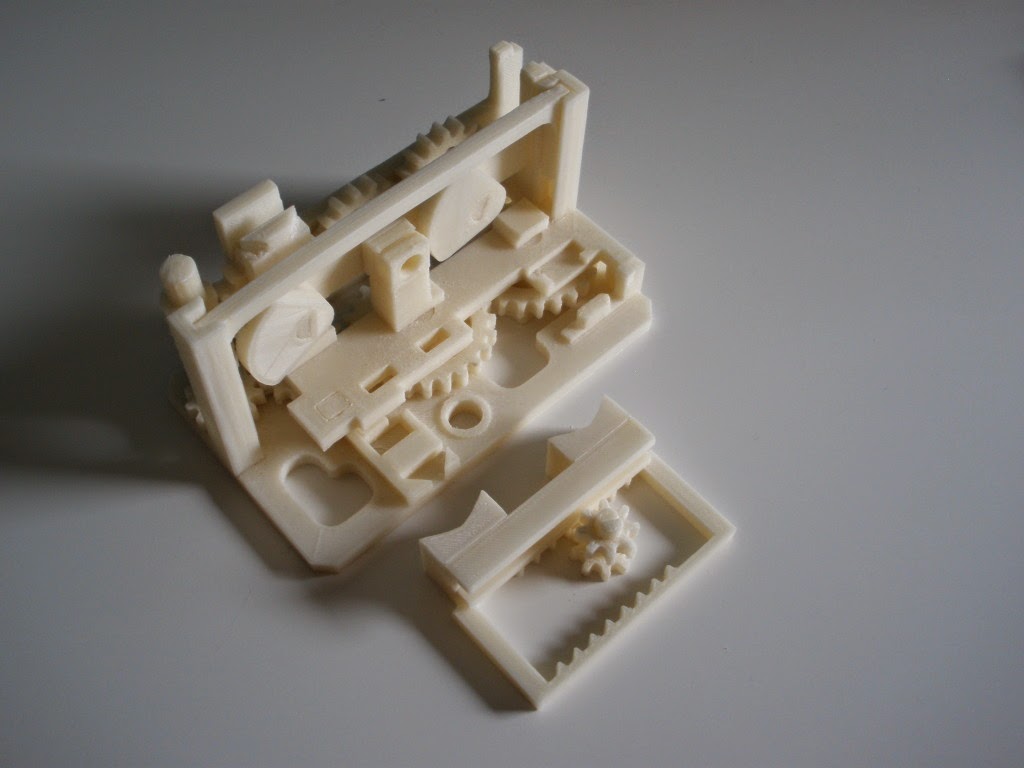

OK enough talking! Here are all the

elements of the “Walking Beam”! Next pictures show the assembly

of the whole machine. Isn't it even more awesome?

I am particularly proud of the

spirals. If you take a closer look, they have different slopes and

one is a single helix while the other is a double helix. For the

double helix system I also had to make the gear with inclined teeth

so it could fit within the gap. Here are some close-up pictures.

Finally I present to you the movie

with the Walking Beam in action!

Thanks for sticking this long. I do

hope you (or at least your inner-geek) enjoyed the content. I had

great fun making this project and am looking forward to doing some

more. Your “views”, “likes” and “shares” are an awesome

recognition to all this effort and for sure will boost my engines to

spend more time on 3d printing. Thank you!

No comments:

Post a Comment