Today is a big day. A truly great day. Its the day when I wired the printer, turned it on, loaded the software and managed to move it! Even better- I did not burn anything!

OK, enough self-applause, back to the facts. I managed to repair the broken path on the PCB board. Note to self- never use cheap solder that you get in supermarket for 1 euro. Well, maybe it is a good solder, but it requires higher temperature to work with. Such power is not provided by my simple 15W iron. In effect, I made the whole area around the "break" dirty with solder. Fortunately managed to clean the short-bridges, and everything works fine. Here is the picture of the repaired board:

Before we move forward, I have to admit that there were some sparks when I tried to measure the voltage on endstops. But it happened only once and were only my clumsy hands making short circuit :P I also had to redo the cables to endstops (signal and voltage were mixed).

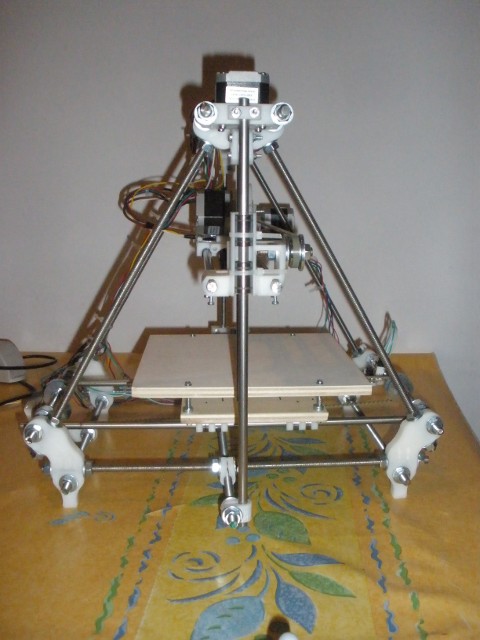

And now, for the pictures of the mounted RepRap that I promised last time (but was to lazy to post).

And FINALLY! The fully mounted, fully wired printer! Of course it still needs calibration and minor fixes, but it moves and heats and measures temperature and reads endstops! It appears that I made the wiring on the "left side" since I had to switch rotation directions for all engines using software. But it works. Second note to self- having experience with wrong wiring of endstops, check the wires of the engines...

Hope you liked this little show off ;) See you next time, when hopefully I will describe how the X and Z jamming were fixed. Also maybe we will put some plastic into the hot-end :) And most of all, I will try to make a movie with the printer working! Hold your thumbs! Ciao! :D